"Portable Wi-Fi" Review

25/03/2022

"Conference X in Tokyo" will be held on December 10, 2021, offline / It was held both online (sponsored by INDUSTRIAL-X Co., Ltd.).

In this article, we will deliver the contents of "Session 1: DX Approach Change ~ DX Practical Measures to be Taken Now and How to Proceed ~" (The speakers are as follows from the left of the photo above).

SpeakerThis session was moderated by Mr. Chire Yago of INDUSTRIAL-X, and discussions developed along several talk themes. The first thing Mr. Yago threw up was the theme, "How do you see the current DX trend?"

First, Mr. Yoshiyuki Arai of Tsubamex answered. Based in Niigata City, Niigata Prefecture, Tsubamex is a manufacturing company centered on the manufacture and sale of molds (joined the Sunstar Group in 2019). After joining the company, Mr. Arai was engaged in the creation of 3DCAC/CAM for mold production, and later worked on the construction of Tsubamex's unique mold manufacturing base "TADD system (Tsubamex Auto Die Design system)" in the IT promotion team. It's here.

Mr. Arai said about the "current DX trend" that the essence of DX lies in "change" (transformation).

"I have been in the mold industry for about 30 years. Looking back, I came across various terms such as office automation (OA), ERP, and PLM. However, in many cases, I did not understand the meaning of those words. Time has passed.In my opinion, they had a strong image of partial optimization.On the other hand, the word DX has the impression that change (change) is brought to the forefront, and I think it has meaning. Up to now, IT has been a tool for partial optimization, and there have been issues such as being unable to connect with the world and not connecting with the overall system. Arai).

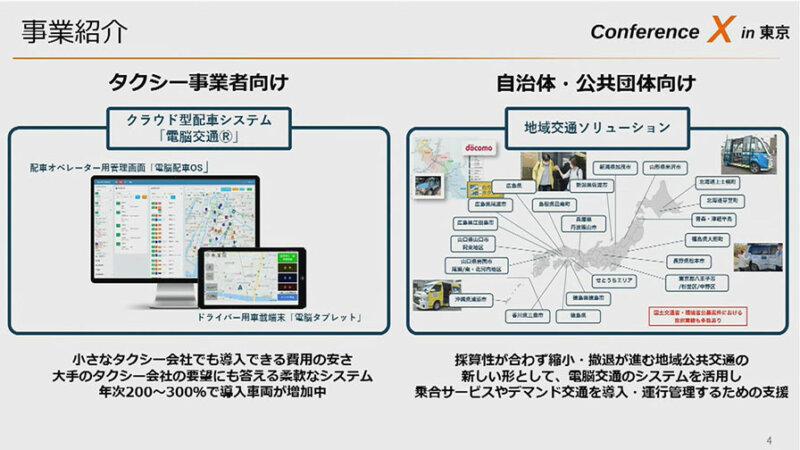

Dennou Kotsu is a venture company from Tokushima that handles dispatch systems for taxi companies, such as "Dennou Kotsu". CEO Yosuke Kondo took over Yoshinogawa Taxi, which was run by his grandfather and was on the verge of closing down, and succeeded in making a V-shaped recovery. Established Denno Kotsu in 2015 and is promoting DX in the taxi industry from the inside from the perspective of the site.

Mr. Kondo said that "DX is progressing now" in the taxi industry.

"The taxi industry has traditionally been analog. We take customer orders over the phone, write down the details in handwriting, and read them out over an analog radio. This series of tasks is prone to errors and requires a lot of man-hours. However, 2015 Digitalization has finally progressed in the taxi industry since 2004.In the aging taxi industry, there is an urgent need to optimize the entire process from the entrance to the exit of business.Therefore, we have begun to face various technologies. , a big movement (that is, DX) is happening” (Mr. Kondo).

Core Concept Technology is a company that provides DX support for companies and IT human resource procurement support. In 2015, Mr. Norinari Taguchi was appointed as Director and CTO, engaged in the study and development of IoT solutions for the manufacturing industry, and currently serves as the General Manager of the Marketing Headquarters. Previously, as an engineer in the manufacturing industry, he was engaged in the development of 3D CAD/CAM systems and research into IoT applications for metal processing.

Mr. Taguchi said that the recent DX trend is that more and more companies are aiming for "overall optimization."

"We receive consultations (DX) from various companies. My impression is that in the past, there were many consultations for partial optimization, but now there are more companies trying to promote overall optimization across the board. For example, changing the form of provision from a product axis to a service axis, etc. Then, the scope will not be limited to individual departments such as manufacturing and design.However, if this happens, there will be a shortage of human resources. Currently, the number of consultations with such personnel is increasing,” says Taguchi.

Continuing, in response to Mr. Yago's question, "Are Japanese companies lagging behind in DX, or are they progressing?" Mr. Arai of Tsubamex said, "Some companies There will be,” he replied. Mr. Arai introduced his own mold manufacturing platform "TADD" system built by the company. It is said that the company has been developing this system with a keen eye for 30 years, regardless of the trend such as DX.

As you can see in the image above, Tsubamex's "TADD System" is an information platform that optimizes the entire mold manufacturing process, from sales and design to final adjustments. Individual systems such as sales and purchasing are linked with each other. “In most cases in the manufacturing industry, the design and purchasing information systems (BOM) are not connected. However, with TADD, purchasing information can be created automatically after the design is completed,” explains Mr. Arai.

In addition, drawings are not made on paper, but mainly through a viewer such as an iPad (upper right of the image above). In some cases, the paper of the drawing is also output, but it is said that it is not necessary basically.

In response to this, Mr. Kondo of Dennou Kotsu said, ``I was impressed when I saw the material (the image above). The structure is similar," he said.

"In the taxi industry, the issue is how to make this process of dispatching more efficient. For example, even if there are 1000 calls a day, it may not be possible to respond during peak hours. So we ( Dennou Kotsu Co., Ltd. breaks down each process of vehicle allocation and creates programs necessary for efficiency.Actually, even with the same number of incoming calls as before, there are no missed calls, and sales have increased by 20%. There is

In the past, we relied on people's judgments, such as "Let's assign this order to that driver." It is necessary to review and automate it. However, the important thing is to convey it carefully to the people in the field. It is violent to say, "Please change this system." While carefully explaining, we have to change little by little. I know this because I actually worked in the taxi industry,” says Kondo.

In addition, Mr. Taguchi of Core Concept Technology, which handles a lot of DX support for the manufacturing industry, said, ``(Like Mr. Kondo), optimizing the manufacturing process and optimizing taxi dispatch are similar. There is a part.Specifically, it is the process design from receiving an order to making things.This is where we use our brains (wisdom and experience) very much.That's why people have to do it, but on the contrary, the bottle It's going to be a bottleneck. If we can systematize it, it's a point where we can greatly increase utilization."

The second theme of this session is "Challenges in Promoting Business Digitally." Regarding this, Mr. Taguchi raised the issue of "human resources."

"In the consultation from the customer, the problems and solutions in DX come out properly. However, the problem is the resources (human resources) to solve them. Basically, we have to hire and train them. No. But it won't grow suddenly.I feel that this is the biggest issue right now.It is important to supplement resources with automation (AI), but what is needed now is human resources who can create such a digital system. (Mr. Taguchi).

On the other hand, Mr. Arai of Tsubamex said that the problem in the manufacturing industry is, ``Even if it is clearly inefficient from a third party's point of view, the person who is doing it does not think it is a problem. )”.

For example, I once monitored the day-to-day work of 60- to 70-year-old field workers, who are said to be craftsmen. From the point of view of the craftsman, that use of time is natural, but from a third party's point of view, it's a waste." (Mr. Arai).

At Tsubamex, each employee is provided with an iPad. We gave iPads to craftsmen who spend 20 to 30% of their time looking for things, so that they could easily see the arrival information and storage locations of things on the viewer. As a result, there is almost no time left to look for things.

Interestingly, Mr. Arai says, "From the point of view of the craftsman, the content of the work has changed only a little, but he does not think that it has become more efficient." In other words, it is necessary to consider efficiency in a third party separately from the individual's awareness and way of thinking about work (discussion on this point will be developed later).

Regarding ``Challenges in promoting digital business,'' Mr. Kondo of Cyber Transportation said, ``The important thing in promoting DX is to be able to responsibly manage the entire DX process from entry to exit. It is the existence of PM (Project Management), but there is a problem that there are not enough PM personnel in any industry."

In addition, according to Mr. Kondo, it is important for the PM not only to have the ability, but also to be able to take responsibility until the end of the project.

“If the PM leaves in a short period of time, such as one or two years, the project often fails. is in charge of management, but the person in charge may disappear (due to transfer, etc.).

On the other hand, if it is a local private company, the mobility of human resources is low, for better or worse. For that reason, there is a PM who will take responsibility for the management until the end. As a result, DX will be promoted. From these points, I think that DX is easier to progress in rural areas. There are many hints for DX in rural areas,” said Kondo.

The next talk theme is "What kind of changes have there been in the (DX) approach and approach?" Two points. The point is how it has changed due to the corona disaster, and at the same time, how will that change be positioned in the history of the company so far.

Tsubamex's Mr. Arai mentioned "remote work" as a major change due to the corona crisis.

"Manufacturing is basically a world of face-to-face. While actually looking at the actual product made, we discuss face-to-face. However, this is difficult during the COVID-19 pandemic, so we have started to remotely check molds using Microsoft Teams. Of course, in the end it is necessary to look at the actual product and check it properly, but three or four checks are required before reaching that stage, and that process can be replaced by remote control,” said Arai.

In response to Mr. Yago's question, "I think it would be difficult to respond remotely at a factory that values the site, but was there any resistance from the site?" Mr. Arai answered that there was. However, from Arai's words below, we can see that it is important to proceed nonetheless, and that it is actually possible.

"The problem is that we (we) think that we are far from IT and digital technology. However, there are IT tools that can be used conveniently by craftsmen, one of which is the iPad.” (Mr. Arai).

The iPad is operated by moving your finger (up/down/left/right). Unlike a mouse, this involves physical movement (the sense of touch in the arms and fingers) for operation. This feeling is highly valued by craftsmen. In fact, craftsmen began to ask us to turn the iPad faster. Next, as you get used to the iPad, you will want more information quickly. Then, it is said that there was also a voice saying that they want a computer this time.

Mr. Arai says, "I think it's difficult to force it. This is especially true for craftsmen in the field. Therefore, it is important to find something that they can use with pleasure. That is also the job of people who are familiar with IT. ' said.

Mr. Taguchi of Core Concept Technology also mentioned the progress of remote work due to the corona crisis. However, he also pointed out that not everything can be done remotely.

“In an IT company like ours, it is often thought that everything is possible remotely. However, this is not always the case. On the other hand, communication with various customers and partners will also be online.However, doing so will inevitably result in poor engagement (relationships with customers)." (Mr. Taguchi).

In relation to the introduction of the iPad by Mr. Tsubamex Arai, Mr. Taguchi said, "The most unfortunate thing (as a solution provider) is not being able to use IT tools in the field. What I need is to first draw a picture that the person in charge on the site will be satisfied with.Without that, we won't be able to move forward (with the PoC).After building a solid consensus, including the site. It's important to start," he said.

According to Mr. Kondo of Denno Kotsu, there was a big change in the taxi industry due to the corona disaster. Call centers, for example.

"Since all taxi companies use landline telephones (for customer service), it was difficult to work remotely. However, last year, due to the danger of clusters, the need to remote call centers became apparent. It's getting higher, and some companies have asked Dennou Traffic if they can do something about it."

Therefore, at Dennou Kotsu, the call center itself has been converted to the cloud, and a system has been built that allows customers to respond to customers at home. It changed the common sense of the conventional taxi industry.

On the other hand, an even bigger change happened. Due to the corona crisis, the taxi company's sales have dropped. As a result, there is a growing trend to change the way of doing business.

"In the taxi industry around 1990, there was a move by each company to set up a cooperative.In order to increase the profit margin, they jointly operated maintenance and fueling stations.Similar to that time. Secondly, due to the corona pandemic, fixed costs would be severe if each company operated their own call centers, so there was a movement among several companies to come together and jointly dispatch vehicles. The taxi industry is in trouble, but it is a big change that joint businesses that were not possible before are taking place,” says Kondo.

The theme of the next talk was "Future Challenges in Promoting DX." Mr. Arai of Tsubamex said as follows.

"At our company, we have created a system (TAD) that controls all the information of manufacturing (of molds) in one system. I want to deploy it to manufacturing companies and use it together with them.”

In addition, Mr. Taguchi of Core Concept Technology said that the goal is to "in-house" DX. “In order to make DX in-house at our customers, it is essential to create an organization for that. We want to contribute to that as well.

Mr. Kondo of Dennou Kotsu said about future challenges, "Digitalization is progressing little by little in the taxi industry, but the market is not doing well. ) alone is difficult, so we would like to collaborate with companies outside the taxi industry to grow the taxi market together.”

On the other hand, Mr. Kondo emphasized the "public benefit" of business.

"DX is a time-consuming initiative. It will not change in any industry. Technological innovation will not suddenly occur tomorrow and the day after tomorrow.In addition, Japan is a society where the population is declining, the aging is progressing, and everything is shrinking. That is why in the coming era, management will be required to create businesses from the perspective of the public interest, not just their own business," says Kondo.

Finally, Mr. Yago points out that what the three companies have in common is that they have “steady” efforts behind the success of DX, and that they have a “reason” from a medium- to long-term perspective. rice field. “Each of us has its own issues, but I would like them to raise their eyes and look at medium- to long-term issues,” says Yako.

Taichi OzakiTechnology and science writer. Master (Applied Chemistry). After working for an oil manufacturer, he has been active as a writer since 2017. He also contributes to scientific journals.