"Portable Wi-Fi" Review

25/03/2022

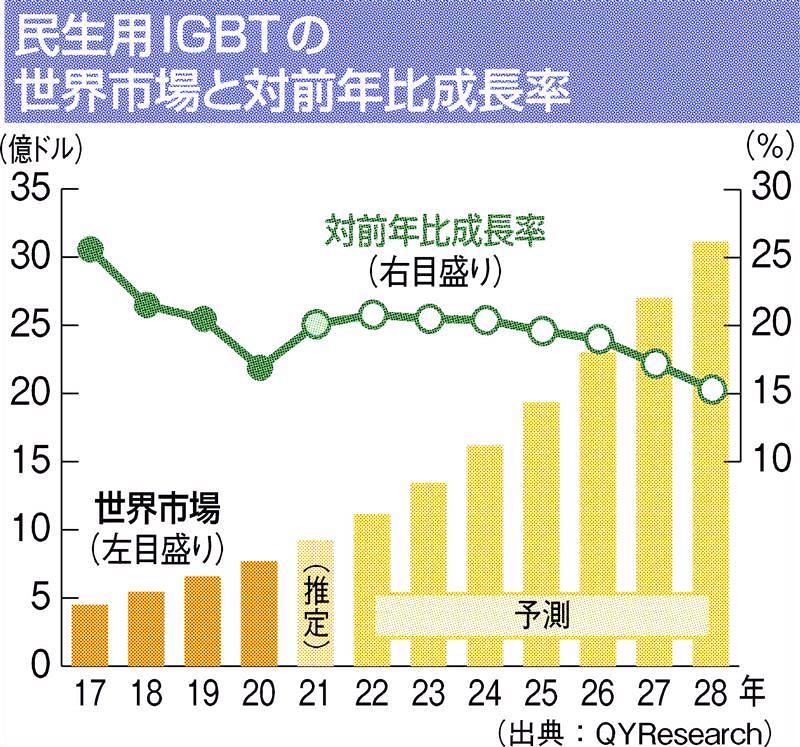

Due to the conflict between the United States and China, semiconductors have become international strategic supplies for economic security.Demand as key parts that are indispensable for social changes such as carbonized carbonization and digitalization for aftercorona, and will affect the production of final products.Just as the Japanese government has launched a factory for the Taiwanese Democratic Corporation manufacturing (TSMC), the reconstruction of the domestic production system of the tip semiconductor is expected to proceed.On the other hand, there is a movement to start domestic production even in commodities (general -purpose) -made power semiconductors.(Editorial committee member, Nishikori Seihei)

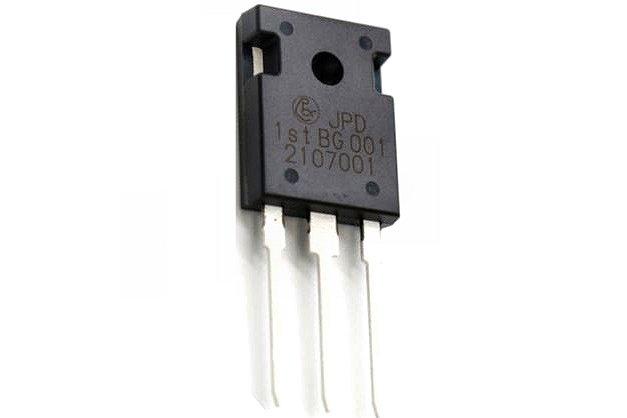

The price has fallen and commoditized for domestic production of consumer power semiconductors starts in January 2021, a fabric semiconductor manufacturer "Japan Power Device" (JPD, Chuo -ku, Osaka City, President Toru Suyama.)is.Production and outsourcing to a supply chain (supply network) called "virtual integration" built with a semiconductor -related company in Japan, and mass -produces IH cooking heater IGBT (insulating gate bipolar transistor) from August.

The IGBT "BG065 Group", which is the first product of JPD, has 650 volts with resistant voltage and a current ampare.Sample will be provided from March.Mass production starts with 100,000 units per month and supplied to domestic manufacturers.In FY2013, the lineup will be expanded and the same will be increased to 1 million.The "BG065 Group" is a package size "TO247", and demand is increasing for consumer and automobiles.

IGBT also works on major domestic companies such as Mitsubishi Electric, Toshiba, and Fuji Electric, but it has become more competitive with foreigners, such as the German Infinin and Technologies, and it is difficult to make new investment decisions for consumer products that are becoming a commodity.

In this situation, JPD builds a supply chain by virtual vertical integration and embarks on domestic production.JPD is in charge of design, development and sales.Production is the domestic semiconductor contract manufacturing (foundory) in the previous process, the rib cuts and chip tests are Estakaya Electronics (Satosho -cho, Okayama Prefecture), and after dice bonds, wire bonds, molds, etc. are Oita Devi Steak (Oita City), trust.The gender evaluation and analysis shall be outsourced to Quer Tech (Sakai -ku, Sakai City).

JPD discloses selling prices for each project and share with companies in each process.Reduce prices in a way that each company takes proper profits.JPD President Suyama is confident that "if we get the last minute price on a honest base, we will not lose to major overseas companies and China at prices."

Prior to mass production, Estakaya Electronics and Oita Devi Technology will increase their production capacity, and from May, they will undertake contract production from other than JPDs.The idea is to "make TO247 thoroughly cheaper in Japan" (President Suyama).Although the price goal is due to soaring raw materials such as copper, it continues to say that "if you can do it in the lower 20 yen range per unit, you can entrust it from anywhere in Japan and abroad."

IGBT is one of the power semiconductor elements.It is used to switch large power at high speed and finely control (turn / off), and is used for industrial equipment and inverters that improve power use efficiency of white goods.JPD produces a product called "discrete", which is packaged with resin with a terminal etc. on one element.

Most of the domestic silicon power semiconductor production equipment is a 6 -inch or 8 -inch line with wafer caliber, and JPD utilizes it.Infinins and others have increased production efficiency on the large -diameter 12 -inch line, but have just begun investing in domestic manufacturers on the 12 -inch line.

Since the power semiconductor flows in the vertical direction of the element, it is necessary to reduce the resistance and reduce the resistance.It is also required to ensure heat dissipation, and says, "There is no merit as a logic semiconductor (performing calculation processing, etc.) to make the circulation width finely integrated with a large diameter," (President Suyama).

-What are the strengths of virtual vertical integration?"It is a supply chain that companies share the vertical integration of major manufacturers for each process. It will take good flexible production and highly costly horizontal division of labor. Each company is also information on market trends from the Company.You can get ready for the next product. "

-What is the background of launching virtual vertical integration with a power semiconductor for civilian?"Even if you develop new technologies and products these days, the technology will spread to the world before taking advantage of the prelate. In Japan, if the top set maker loses the world competition, the supplier will also lose., Sometimes it will withdraw even though it is a cost. If it is difficult to continue commoditized products with a comprehensive electronics manufacturer, the design that is the strength of Japan will be shared by a full -time profession.You can leave production in Japan "

-Most of the virtual vertical integration made with the LCD driver IC has moved to China."Television's global demand has stopped increasing, and the number of domestic users has decreased. RDJ has supplied products to domestic manufacturers at the cheapest price for three years after its foundation. The production has moved to China., RDJ design is left in Japan and employment is increasing. In the case of an LCD driver IC, it was design process that could be left in Japan. "

-What is the possibility of virtual vertical integration of power semiconductors for civilian?"IGBT is increasing in demand. Unlike the LCD driver IC, there are various uses. The production capacity of Japan's 6 -inch and 8 -inch lines is the best in the world alongside Taiwan, which can make use of this strength. First of all, 6 in Japan.The first step is to find a way to win on the inch, 8 -inch line. It is difficult to win even if it is large in the same way as the 12 -inch line of the preceding infinnion. "

After serving as a director of the Driver IC business for the display at Panasonic, Suyama was independently founded a ribbon display Japan (RDJ, Shimogyo -ku, Kyoto), a Fabeless manufacturer of an LCD driver IC for television.RDJ has built a virtual vertical integration similar to JPD and has mass -produced driver ICs for domestic LCD manufacturers.

However, the production of liquid crystal manufacturers has decreased in Japan, and demand for driver ICs has declined.In 19, RDJ became a subsidiary of Shenzhenchy Kae Electronics (Shenzhen City), which was established by President Suyama with investors and others in China.RDJ's sales of about 5 billion yen in the fiscal year ended December 2001.Currently, the previous process is outsourced to Japanese and Taiwanese companies, and the postage is outsourced to China, and it is supplied to Chinese LCD manufacturers.

President Suyama, who is also a senior vice president and highest technical manager (CTO), said, "Most of the LCD driver IC users have become Chinese companies and Chinese products are given priority."Explains the background of the transitional vertical integration.

Nikkan Kogyo Shimbun January 14, 2022